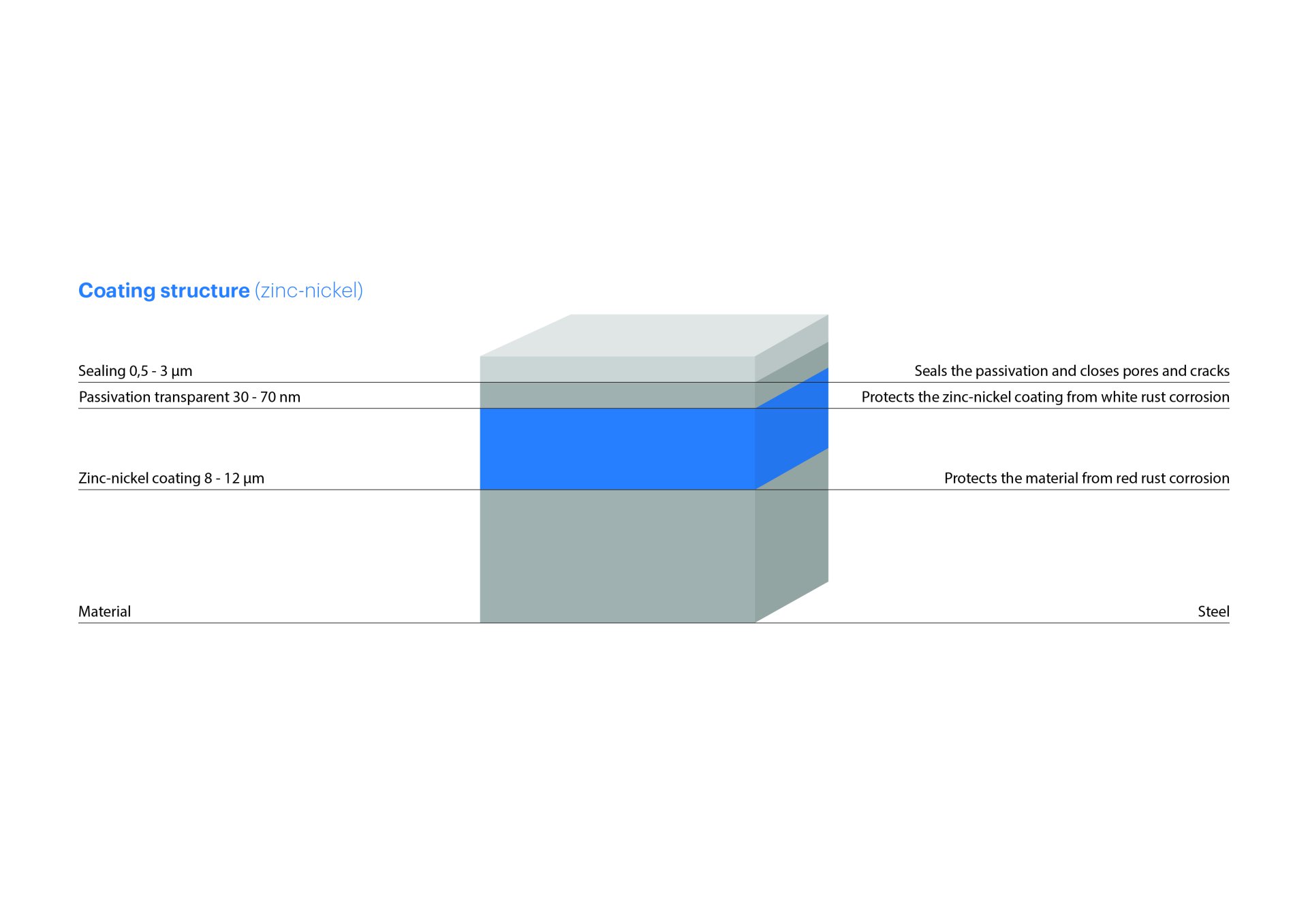

Zinc/nickel surface treatment

With a zinc-nickel surface treatment, Hydynamic offers you the best coating currently available in the field of cathodic corrosion protection for steel. The galvanically applied zinc-nickel alloy, consisting of 12 to 15% nickel, has proven itself especially in applications where extremely high corrosion resistance is required.

Zinc-nickel coatings are used when traditional electrolytic galvanizing does not meet life-time requirements, for example due to exposure to high temperatures or aggressive environmental conditions. In recent years, this technology has undergone significant developments to meet the increasingly stringent standards of the automotive industry. Today, more and more companies in a variety of industries are making the switch to zinc-nickel coatings because of their superior corrosion protection.

Benefits:

- Superior corrosion resistance (according to EN ISO 9227) > 720 hours NSS.

- High coating and base material corrosion resistance

- Environmentally friendly chromium(VI)-free surface treatment

- Maximum corrosion protection even at high thermal loads

- No residue in internal mounting applications and screw threads.

- Excellent transparent and black appearance

- Resistant to all common hydraulic fluids

- Proven standard among European car manufacturers for years

- Friction coefficients adjustable according to automotive industry requirements